Features:

- Perfect match for different automatic devices

- Inverse reverse rotation design for smooth operation

- High load bearing capacity

Usage:

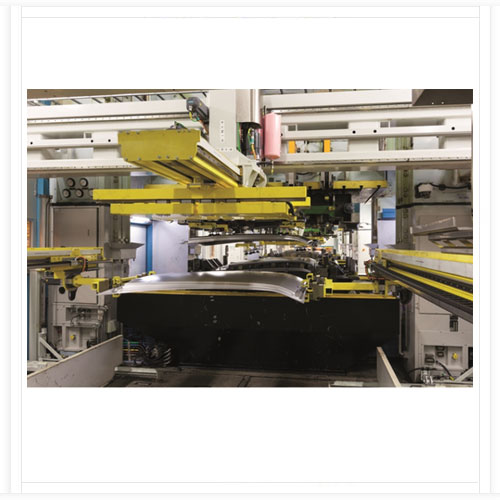

- Heavy duty industry

- Motor core lamination with automatic stacking

Main Structure Feature:

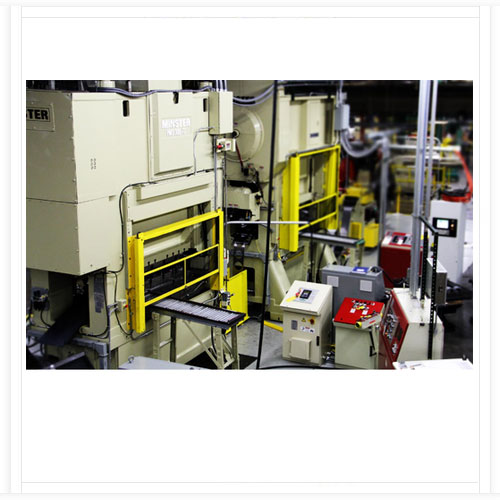

- Makeup: uncoiled, S-type material straightened. Gear exchanger of feeder, lubricating device for material, closed-type double-crank high-speed precision press

- Separated-structure and high-rigidity cast iron frame , based and crossbeam are tightened by four tensile screw rods, with high rigidity and less angular deformation

- Imported pneumatic combination friction clutch-brake, with low noise, long service life, large clutch torque and small braking angle, to ensure reliable safety and flexible action

- The machine has dynamic balancing system, reducing the noise from vibration, extending the service life of the dies and improving working environment

- Automatic oil-forced lubrication system .and alarming functions for oil route failure

- Frequency control motor is adopted .with adjustable strokes

- Programmable cam controller (encoder). To ensure convenient operation and reliable Performances

- Automatic temperature control system and using the thermal compensation technology to control the position of bottom dead center in high precision, Four-point crankshaft supporting structure, enhancing the strength of crankshafts, less deformation .high rigidity and strong load deviation resistant capability (80-300T)

- The structure of guide column and guide pin bushing is adopted, completely eliminating, the side force produced by connecting rod on the slide in swing, ensuring the precision of the slide (80-300T)

- Slide is guided by clearance-free ball bearing guide column and guide pin bushing, ensuring the precision of the slide (80-300T)

Product Details :

| Automatic Grade | Automatic |

| CNC or Not | CNC |

| Electric Power (Kilowatt) | 50 |

| Load (Ton) | 0-30 Ton, 30-60 Ton, 60-90 Ton, 90-120 Ton |

| Power Source | Hydraulic, Mechanical, Pneumatic |

| Type | H Frame |