Versatile

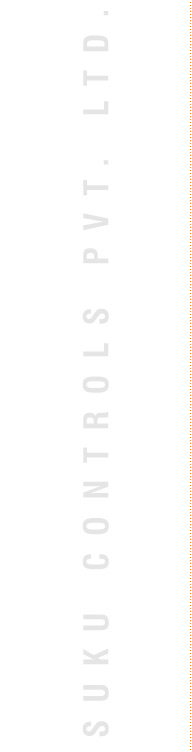

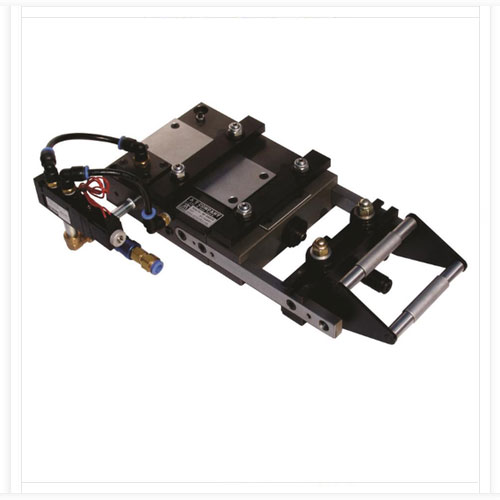

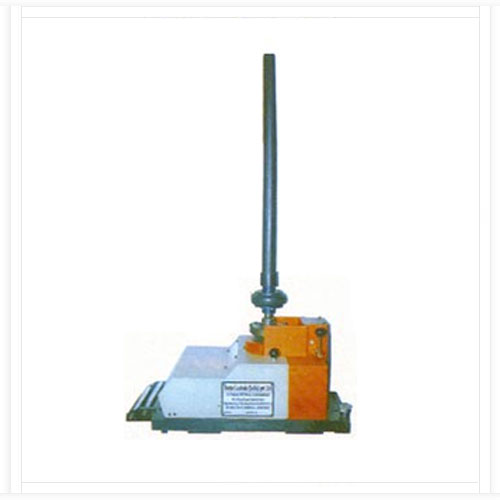

Coil stock can be fed in any direction or angle at any time during the machine cycle. A single feed can push or pull through long or short progressions.

A variety of stock widths and thicknesses can be fed at different speeds and feed lengths. Two or more strips can be simultaneously fed by the same feed.

How To Select a Feeder?

Max. width of your strip in coil form ...mm

Max. stroke length of your feeding ...mm

Max. Min thickness of your strip ...mm

Max. Strokes per minute of press..

Product Details :

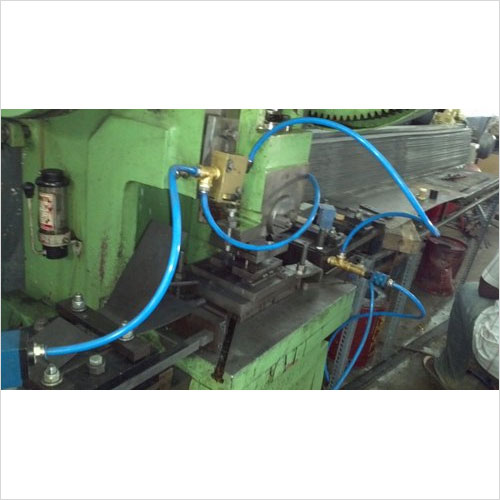

| Automation Grade | Semi-Automatic |

| Machine Type | Poultry Feeding Machine |

| Production Capacity | 500 Kg - 1 Ton/ Day |

| Driven Type | Electric |

| Air Pressure | 5 to 7 Kg |

| Material Width | 50 to 1000 mm |